Manufacturing

(Food & Beverage • Warehousing & Logistics)

Prevent small misses from becoming big food safety and quality events.

Command Center helps manufacturing teams prove critical procedures happened (who/when/where + evidence), escalate exceptions in real time, and verify closure—so standards hold across every shift and line.

Why Operating Procedures Determine Success in Manufacturing

In healthcare, people rely on the building and the equipment around them working the way it should—every day, every shift.

Even with strong programs, breakdowns happen when:

Procedures drift across shifts, supervisors, and lines

Checks are done on paper, then backfilled later

Exceptions get recorded, but corrective actions aren’t consistently closed

The plant “passes audits,” but daily reality isn’t visible

In Food & Beverage, those gaps can turn into quality escapes, rework, claims, or recalls.

When procedures are verifiable, you get fewer preventable issues, faster response, and defensible proof, without adding more admin.

Explore what Success Looks Like

Choose your environment to see what success looks like, and the critical procedures to start with.

Food & Beverage Manufacturing

What success looks like: critical checks executed consistently across shifts—exceptions escalated fast and corrective actions closed with evidence.

Warehousing & Logistics

What success looks like: safety and readiness routines completed consistently—defects and hazards escalated quickly with verified close-out.

Where to Start in Manufacturing

Start with one high-risk routine. Prove it end-to-end. Then scale.

Start with one routine tied to food safety, quality, or downtime, then expand.

Pre-op / sanitation verification (ready-to-run with proof)

Critical checks and readings (temps, pressures, pass/fail, corrective actions)

Allergen / changeover procedures (line clearance + verification)

Receiving and storage checks (conditions, temps, exceptions)

Preventive maintenance rounds (readiness checks + close-out proof)

High-risk area safety rounds (slip/trip, forklift zones, hazards)

Warehouse equipment readiness (if applicable: inspections + defect escalation)

A Simple Promise (no fluff)

Prove execution. Escalate exceptions. Verify closure.

Make food safety and operational readiness verifiable because “we did the checks” isn’t enough.

Ready to make critical procedures verifiable?

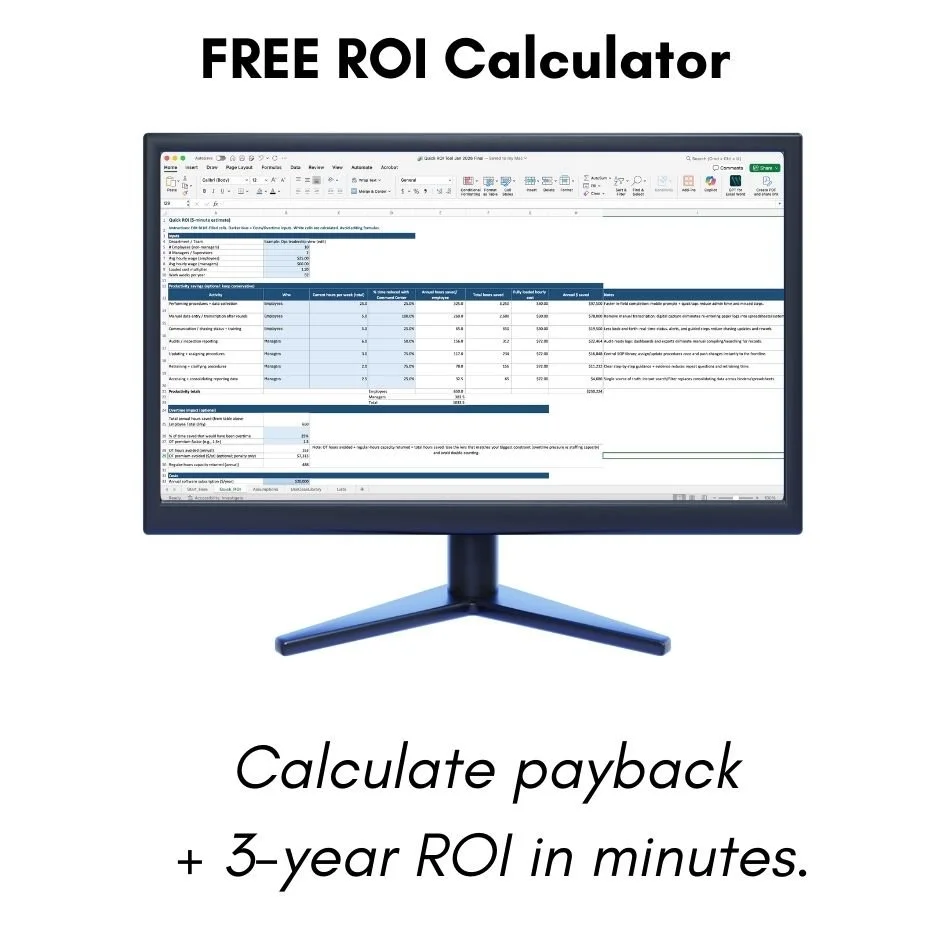

Watch the 90-second demo, model the ROI in minutes or learn about the opportunity with IoT.

Start with one procedure. Expand fast. No rip-and-replace. Built for frontline adoption.

Ask a question or request a walkthrough.

We’ll reply within 1 business day.

Get In Touch

Email: info@zendelity.com

Phone: 613-369-4330

Suite 202, 308 Legget Drive,

Kanata, ONT, K2K 1Y6